Our assortment includes more than 100 types of products: whole milk and sour milk, meat and sausage products, cheeses, rice cereals, ice cream, soft drinks and baked goods.

Our assortment includes more than 100 types of products: whole milk and sour milk, meat and sausage products, cheeses, rice cereals, ice cream, soft drinks and baked goods.

The total number of cattle is 6631, three thousand of which are dairy herds.

Kizlyaragrocomplex JSC has three livestock complexes. These are

Nekrasovsky, Uritsky, and the largest of them is located in the village of Chernyaevka, Kizlyar

region. It is equipped with powerful modern equipment that meets all the requirements of the latest

technology.

Twice a day cows are driven into the milking parlour. The whole process is automated, this

completely eliminates the contact of milk with the external environment. Up to 15 liters of selected

fresh milk per day comes from each animal. It is collected in cooling tanks and immediately sent to

the factory.

The quality of milk and meat directly depends on the nutrition of the animal. A powerful food base is harvested annually during the season, most of which is made up of feed of our own production.

Cereal crops are grown on an area of 3826 hectares - barley, wheat; alfalfa; corn for silage.

The lands of the Kizlyar region are a favorable environment for growing rice. Here the soil is rich in minerals, which has a direct impact on the quality of the crop. Rice growing is an important branch of agriculture for us. Favorable climatic conditions and fertile soil, modern high-tech equipment, coupled with the work of qualified specialists, are bearing fruit: every year we get a rich harvest of rice.

The crop area is 1200 ha. On average, the yield per hectare reaches 63 centners.

We mainly grow Regulus rice. Recently, the assortment has been replenished with a line of premium varieties of cereals.

Whole cow's milk is the basis of our production. Regularly, the staff of technologists conducts a full range of laboratory studies, from the moment raw materials are received to the release of the finished product. All products comply with GOST standards. In our production, we fundamentally do not use preservatives and substitutes for natural milk. The priority is the release of a natural high-quality product for a healthy generation.

Our cheeses are made from selected cow's milk only. The process of their manufacture is a whole science with its own secrets. The natural raw material base and the skill of highly qualified specialists allow us to achieve the perfect taste and quality. One of the important ingredients is sourdough. Each sourdough is carefully selected, which takes into account a large number of indicators, including compliance with halal standards.

The assortment has everything: from fresh pickled to aged, including traditional Caucasian cheeses and cheeses according to Italian recipes - mozzarella, gouda, cachotta. There are 8 varieties in total.

Special attention is paid to the production of meat products. Every day, fresh meat of animals grown exclusively in our own livestock complexes enters production. The slaughter takes place strictly in compliance with the norms of Islam. Freezing raw materials are not subject. The meat is processed chilled.

Boiled and semi-smoked sausages, frankfurters, sausages, deli meats and convenience foods. More than 30 types of products in total.

It is important that meat products contain food additives that

are unacceptable and harmful to human health. The ingredients are beef, poultry and spices. All

products comply with HIalal standards.

We care about the health of our consumers.

Kizlyaragrocomplex is one of the largest enterprises in Dagestan for growing, processing and packing rice. The industry is developing dynamically. Innovative technologies are being introduced, new varieties are being developed.

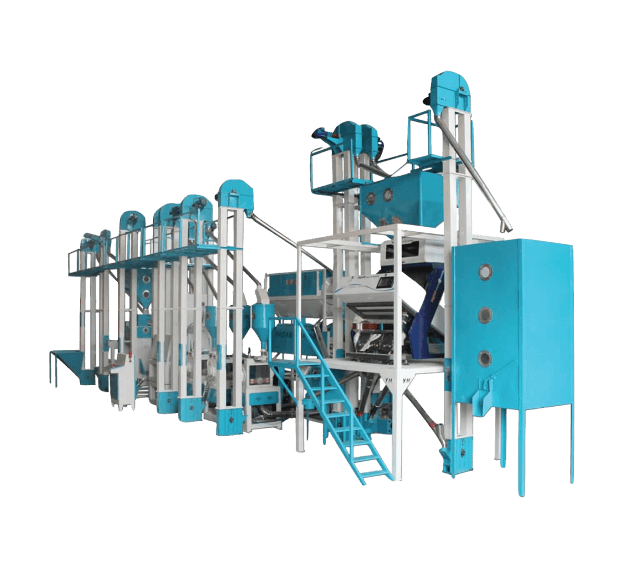

In 2016, a rice cleaning and processing plant was put into operation. It is equipped with modern Turkish-made equipment, which allows you to get a product that meets international quality standards. The enterprise is capable of receiving and processing up to 150 tons of raw material per day.

Three degrees of rice cleaning allow you to achieve excellent quality without losing useful properties:

In 2016, the assortment of products under the Darman brand was replenished with a line of bakery products.

There is a unique Turkish stone oven that is fired with real wood. The bread in it is baked according to a special recipe using the author's sourdough. It takes much more time, but the result is worth it - ruddy fragrant bread turns out not only tasty, but also healthy. Wheat, rye, whole grain and yeast-free bread loved by many.

Kizlyaragrocomplex's trading network consists of 60 branded kiosks and shops in the cities of Makhachkala and Kizlyar, and more than 2,000 partners in the wholesale and distribution networks.